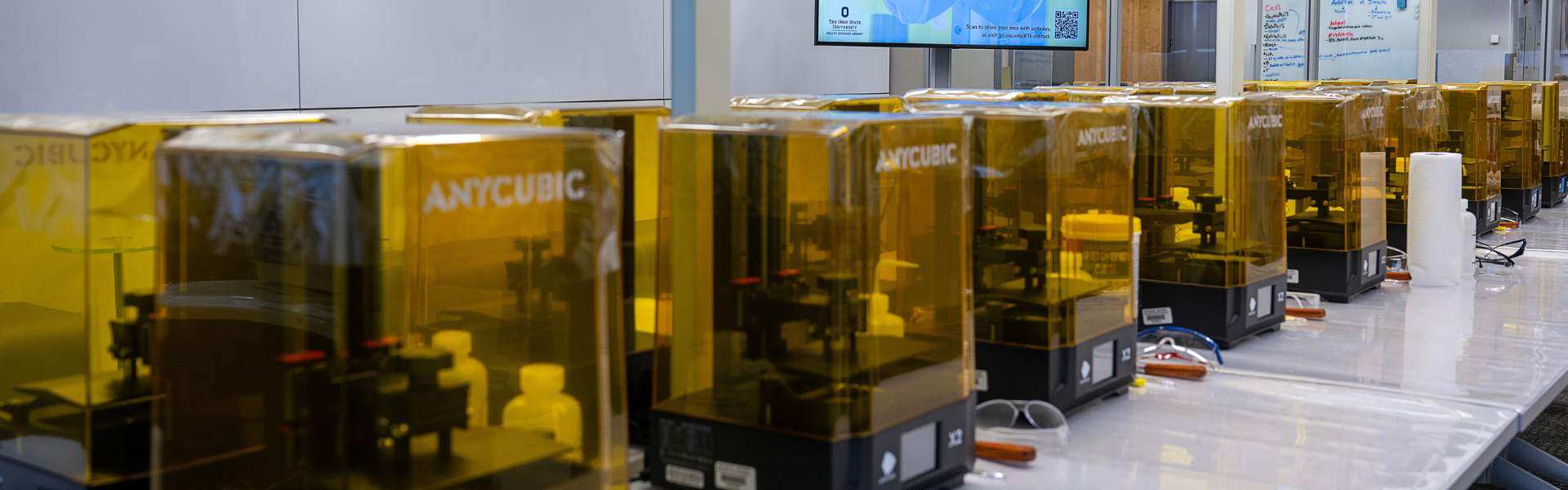

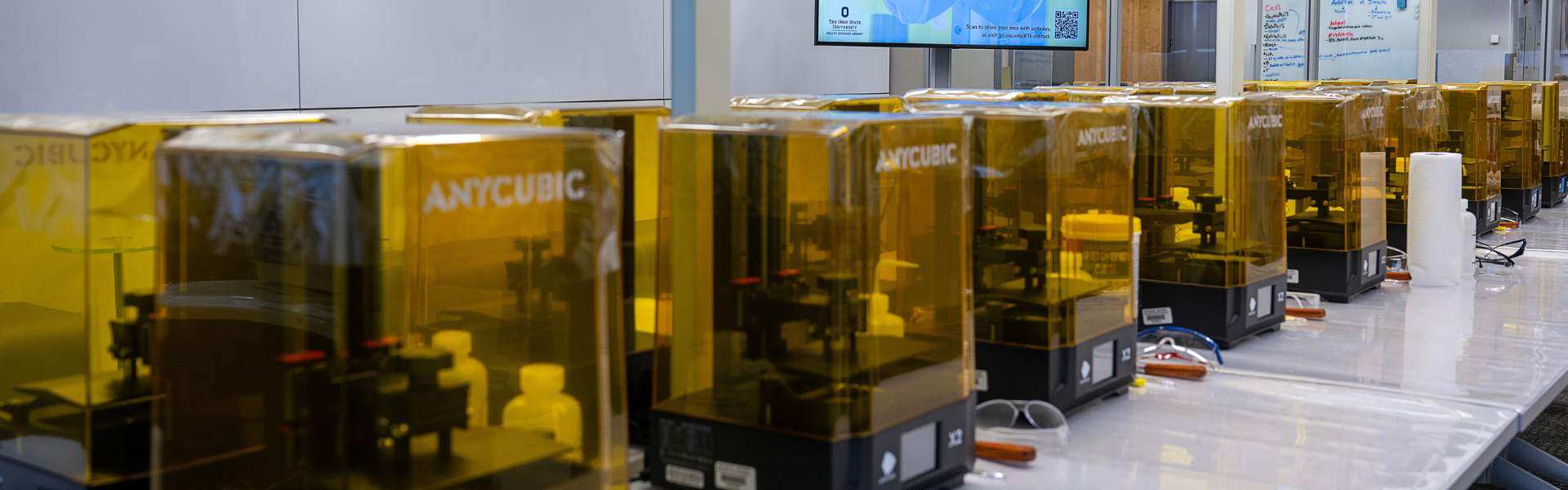

3D Printing Lab Gets 19 Upgraded Printers

The EdTech Incubator’s (ETI) 3D Printing Lab is now equipped with 18 upgraded resin printers and one filament printer. With new and enhanced capabilities, you can bring your imagination to reality. This upgraded equipment enhances our printing capabilities and supports the ongoing commitment the ETI has to innovation and research.

Why We Upgraded

Our decision to invest in new printers came from the wear and tear of our previous printers. The 3D Printing Lab is the most-used innovation zone at the ETI and often has large groups maxing out on the printers, increasing the need for printers that run smoothly. The first set of 3D printers we had were ANYCUBIC 1.7L resin printers, and when it came time to replace the worn-down equipment, we needed something with higher resolution and more capabilities.

Older Capabilities

Our previous printers were able to print multiple items on a single plate if they are the appropriate dimensions and size, but they had a smaller print bed. Depending on how many layers are needed for the 3D print, printing could take anywhere from 30 minutes to several hours. This is something we kept in mind when upgrading to the new printers. New Capabilities One of the big differences from our old printers is the size. Our previous printers had a smaller print bed with the approximate dimensions of 5” 3” x 6” and limited us from partnering with individuals on certain projects. Our new printers have significantly larger build volumes, which allows us to accept a wider range of projects and be able to facilitate more research initiatives as well. Our new Anycubic Photon Mono X2 printers also offer 4K to 8K resolution, which allows faculty, students and physicians to achieve incredible detail and texture in prints.

Additional Filament Printer

In addition to our new resin printers, we also added a filament printer to our lab. This new addition allows us to explore printing with different materials that would not be possible with vat photopolymerization or Stereolithography ( SLA) printing. The difference is that SLA is more similar to liquid printing; the filament printer operates using spools of material. It allows up to five active colors, a sensor-inspected first layer and employs a Core XY system with an acceleration of 20,000 mm/s². This new filament printer expands our ability to create more durable prototypes as well as functional parts for various projects.

Have questions about ETI 3D Printing Capabilities? Reach out!

We continue to offer the ETI space for community and educational use, ensuring the resources needed for all steps of your 3D printing projects. We are excited to see how our new printers can help enhance your skills and foster amazing creativity in the lab. Stay tuned for upcoming workshops to help you get the most out of the latest technology! For any additional information or questions, feel free to contact us .